4D-FRPE-250 1/4” x 250’ Double Flame Retardant Polyethylene Tubing Black

Application

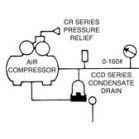

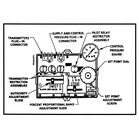

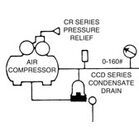

Pneuline Flame Retardant Polyethylene Tubing is a superior quality, flame retardant, stress crack resistant, exclusively compounded polyethylene tubing product for use in pneumatic instrument control applications.

Marking

Pneuline black tubing is marked with a white ink numbering system over the full length of the tubing. Bright

color stripes are extruded directly into the outside surface of the tubing and provide permanent color-coding

that will not wear or fade.

Identification

When color-coded, the combination of color stripes and printline numbering provides for up to 210 pneumatic circuit lines without duplicating a color stripe-number combination.

Stress Crack Resistance

Resistance to stress cracking is critical. The possibility of tubing failure occurring behind skyscraper walls 10 or 15 years in the future is of great concern. Since stress crack resistance is one of the most important physical properties of polyethylene instrumentations tubing, Performance Pipe has devised its own test to determine its true value. ESCR test is patterned after the ASTM D1693 test for “Environmental Stress Cracking of Ethylene plastics” but is a much tougher and more stringent test than ASTM D1693. Our 48-hour, 70°C accelerated aging test produces crystal developments within the polymer that would otherwise take years to develop. Tubing samples are then bent into a "V" shape and aged in a chemical stress cracking solution at 50°C for 200 hours.

Flame Retardant

"Flame Retardant" or "self-extinguishing" means that the tubing material has the ability to retard burning and extinguish the flame once the flame source is removed. Industry tests are used to evaluate the burning characteristics of pneumatic tubing materials. ASTM D 635 Standard Test Method for Rate of Burning and/or Extent/Time of Burning of Plastics in a Horizontal Position test materials for horizontal burn rate.