LF24-SR - Damper Actuator Modulating, Spring Return, 24 VAC/DC, for 2 to 10 VDC or 4 to 20 mA Control Signal. Torque minimum is 35 in-lb, for control of air dampers.

Application

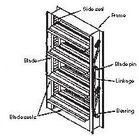

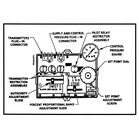

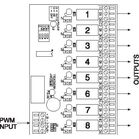

For fail-safe, modulating control of dampers in HVAC systems. Actuator sizing should be done in accordance with the damper manufacturer’s specifications. The actuator is mounted directly to a damper shaft from 3/8” up to 1/2” in diameter by means of its universal clamp, 1/2” shaft centered at delivery. For shafts up to 3/4” use K6-1 accessory. A crank arm and several mounting brackets are available for applications where the actuator cannot be direct coupled to the damper shaft. The actuator operates in response to a 2 to 10 VDC, or with the addition of a 500Ω resistor, a 4 to 20 mA control input from an electronic controller or positioner. A 2 to 10 VDC feedback signal is provided for position indication.

Operation

The LF series actuators provide true spring return operation for reliable fail-safe application and positive close-off on air tight dampers. The spring return system provides consistent torque to the damper with, and without,

power applied to the actuator. The LF series provides 95° of rotation and is provided with a graduated position indicator showing 0 to 95°. The LF24-SR US uses a brushless DC motor which is controlled by an Application Specific Integrated Circuit (ASIC) and a microprocessor. The microprocessor provides the intelligence to the ASIC to provide a constant rotation rate and to know the actuator’s exact fail-safe position. The ASIC monitors and controls the brushless DC motor’s rotation and provides a digital rotation sensing function to prevent damage to the actuator in a stall condition. The actuator may be stalled anywhere in its normal rotation without the need of mechanical end switches. Power consumption is reduced in holding mode.