Air Compressor Ordering Tips

How To Order Compressors

NECC offers you this simple to follow guideline to use when ordering a new or replacement compressor. Call us at 800-227-9800 and we'll walk you through the process.

A. Compressor Sizing Formula For New Installations or Replacement:

- Count the devices connected to the control system that use air.

- List the model and function of each device.

- Look up the air use (in scim) in the factory manuals.

- Total the air consumption of your control system (in scims).

- Divide the scims (Standard Cubic Inches/Minute) by 1728 to determine CFM.

- Multiply the CFM by 3 (this will give you the recommended 1/3 run time needed to assure maximum life and drier supply air).

B. For EXACT Compressor Replacement:

- Try to find the exact model#, serial # and the manufacturer's name of the compressor you are replacing.

- Determine anything special about the existing installation (voltage, accessories, special size tank piping, air station components, etc.)

C. MINIMUM Ordering Specifications:

- Capacity (delivered CFM output desired.)

- Size (hp. of the compressor.)

- Tank Size (in gallons.)

- Voltage and Phase (of the compressor motor.)

- Simplex or Duplex (one pump or two mounted on the tank. Duplex gives you longer life and standby capacity in the event of a pump failure.)

- Type of Compressor (lubricated or oil-less.)

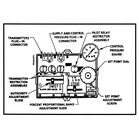

- Pre-Mounted, Pre-Piped Drier Option (saves installation time.)

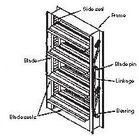

- Any Air Station Accessories Needed (regulators, condensate drains, relief valves, oil and air filters, pressure gauges, etc.)

- Installation Accessories (tank vibration pads, fittings, tubing, Teflon tape, restrictors, in line check valves, tubing tools, mounting clips, ty-wraps, spring clips, etc.)